Our Specialties

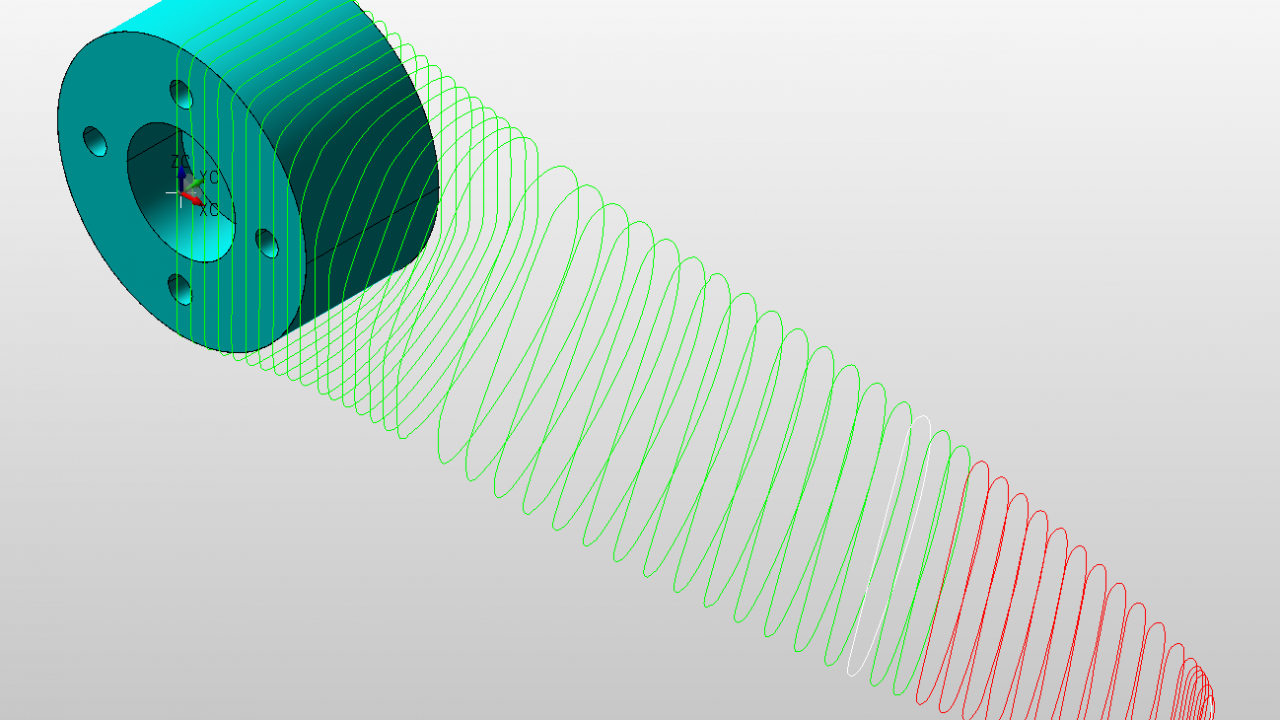

Machining

Casting Targeting & Full Machining, Gate Removal, Adaptive Machining, Billet Machining

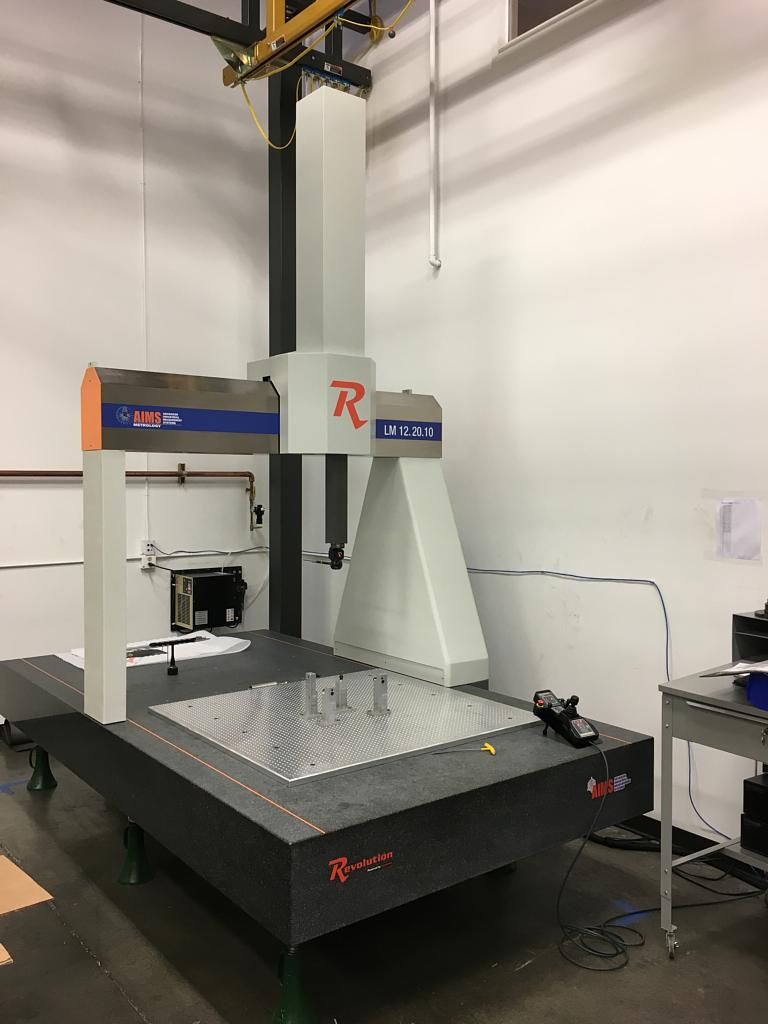

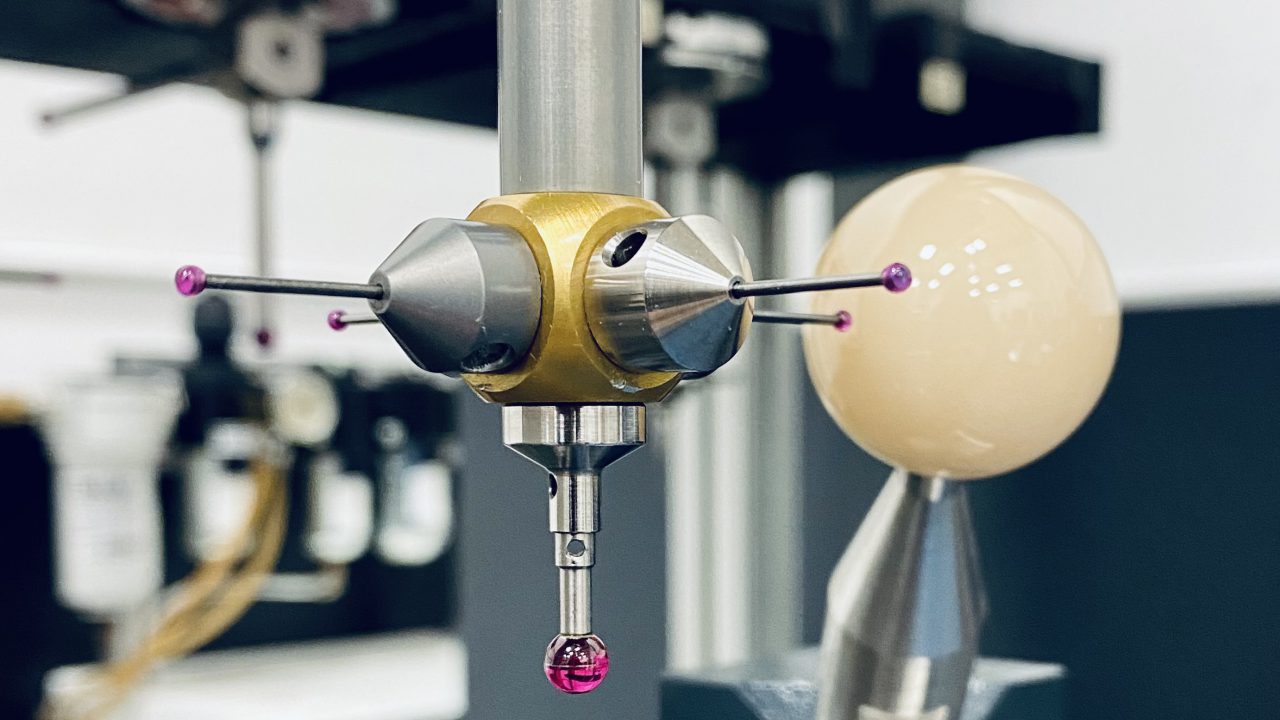

Read MoreInspection

First Articles, Production Inspection, Capability Studies, Reverse Engineering, PPAP

Read MoreData Handling

Equipment linking, Historical Database, Program Revision Control, Custom Reports, Statistical Tools

Read MoreNews

New DMU 85 5-Axis

10/29/2018 - Here at…

New Parts Washer

Because of Integrated's constant…

New DMG Mori 3-axis

Equipment Upgrade - Integrated…