We provide a full array of Inspection services including First Article, Engineering Evaluation, PPAP, and Process Capability Studies. We operate nine Coordinate Measuring Machines for contact inspection and a Micro-Vu vision system for non-contact inspection. Our Senior Metrologists are GDT certified level III and all have had schooling in basic statistics needed for process evaluation. Our Coordinate Measuring Machines are networked with our proprietary MetBase data collection and revision control system. We maintain full calibration on all of our inspection equipment.

Fitting

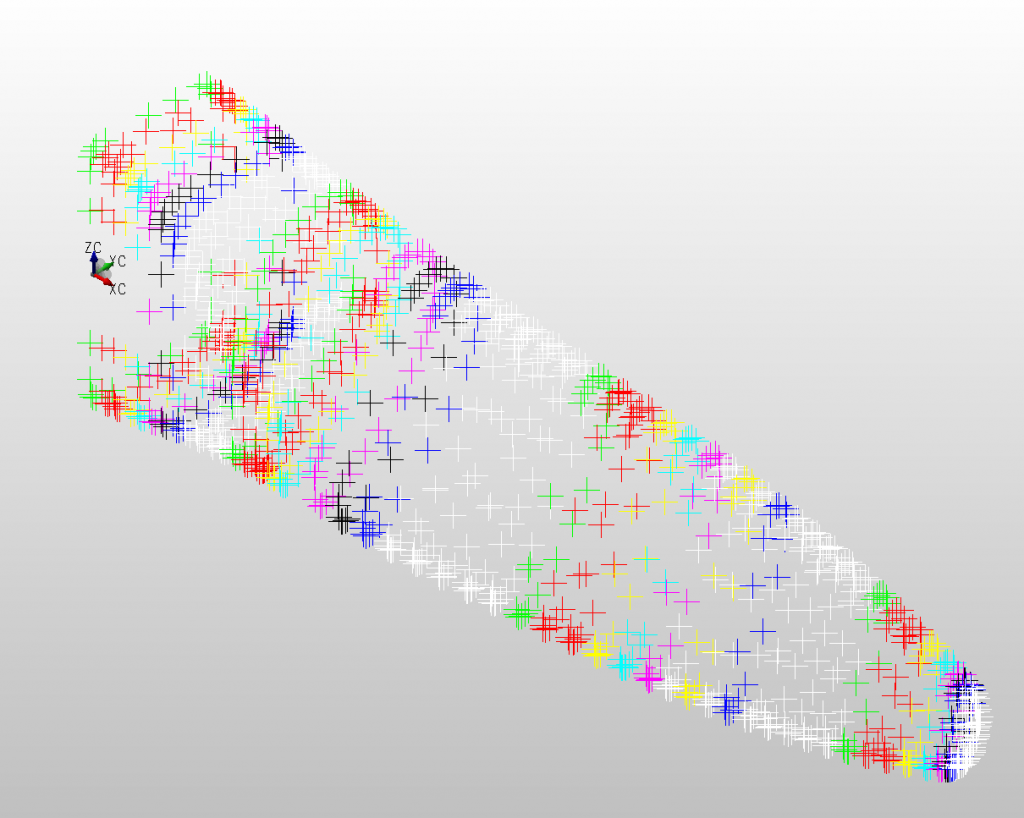

When it comes to near net shape geometry, no one is better than Integrated at finding its optimized 3 axis rotation. Since all of our inspections are cataloged in MetBase, we have access to aggregate data. This capability allows us to examine near net shaped geometry as the product of a process, as opposed to itself with the assumption the process is repeatable. Many times we are able find the best fit of a geometric shape within a process that will deliver an acceptable machining. Our customers use us because we can find the proper dimensional centroid for the geometry they are trying to produce. Our data mining capability is what gets us there. We employ the same engineering techniques when developing in house machining processes. For production processes we typically provide fixture design, fabrication, and assembly utilizing our manual machine shop.

Fixture calibration

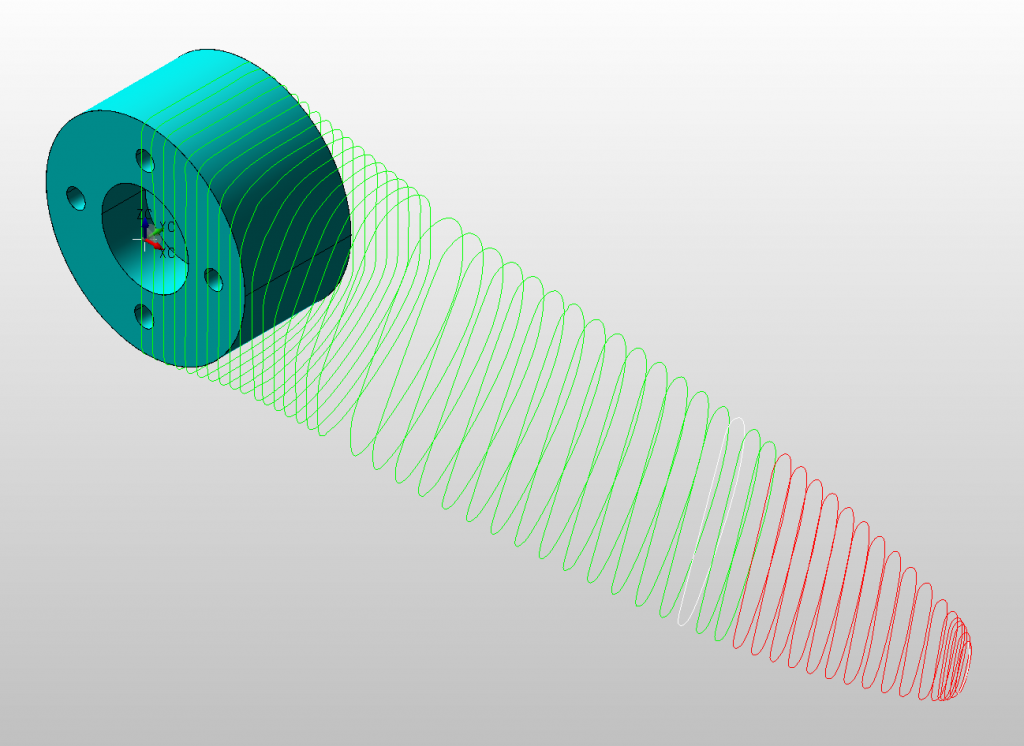

Reverse Engineering

IIS also has the ability to measure ball center data on its CMM’s, export to CAD software, and create splines/solids for a customer to then create a true model. Depending on the requirement or the complexity, we have also created the full model as well.