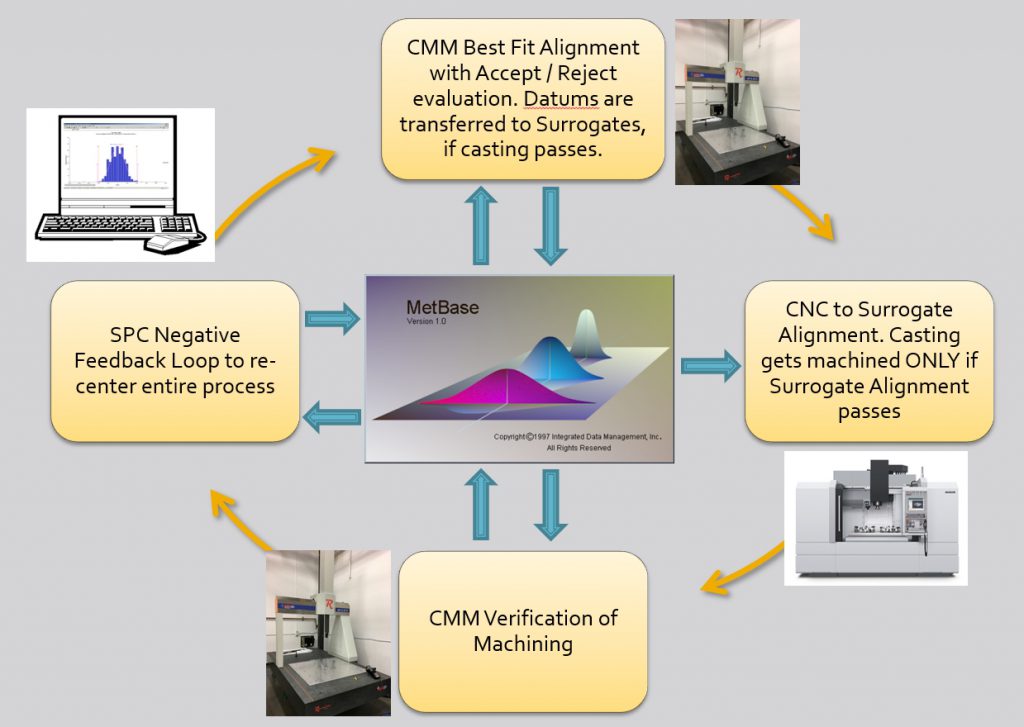

We operate three 3 axis and two 5 axis CNC’s. All of our CNC’s are linked to MetBase and driven by CMM data. We have real time, forwards and backwards (revision) control for all CMM and CNC part programs.

Why is this process a big deal? Please view our reject rate below.

Target Machining

IIS operates a proprietary 4 sigma targeting system that was developed in 2001, and have Target Machined in excess of one hundred thousand castings with a lifetime reject rate less than 1.7 castings per thousand ( 1/1000 in 2016). We are not aware of any other vendors or customers with this capability. We primarily target machine Industrial Gas Turbine, and Aerospace Components. The processes are developed in house and utilize Statistical Process Control to ensure conformity.

It is not uncommon for a manufacturing process to drift 1.5 sigma over time. All of our processes are designed to be fail safe. Integrated utilizes a feedback loop to monitor and maintain process control.

Are we going to make a mistake? Statistically we have to, but our persistence for high quality manufacturing differentiates us from the infrequency of occurrence. We are unaware of any other shops using this strategy.

Full Casting Machining

Though IIS has mastered the targeting process, we are not limited to targeting only. We believe there to be a significant cost/time savings, by reducing or eliminating targeting operations and tackling the majority of the downstream machining operations all in one shot. By doing this, we also avoid tolerance stack-up from target fixtures.

Located Gate Removal

Removing gate material within a specific tolerance relative to adjacent cast surfaces is easily achieved by our proprietary software Metbase‘ ability to transfer CMM values directly to our CNC machines. Overall(and local) casting variation is compensated for by a poor mans adaptive machining process that requires minimal CMM pts and CNC processing to move the machining CAD geometry around. Depending on the rough cut of the gates, and our customers final finish requirements, we are able to rapidly and accurately remove/trim gate material in production.

Adaptive Machining

In situations where casting variation is too much for traditional CNC gate removal, or the requirement is to remove material completely flush with a complex cast surface, true “adaptive Machining” is required. Linking our newer 5-axis CNC’s to Metbase has enabled us to achieve this. This technology not only allows us to meld a CAD model into a casting, but to “deform” the CAD model to match the true casting. We are able to do this by merging deviations from the CMM into a CNC CAM program. Every CNC program is unique to the geometry it is cutting, and every CNC program is created on the fly. Our first try at this was trailing edge gate removal on Industrial Gas Turbine blades, followed by core-support pin “blips”. There is little if any notching, limited only by the CMM point density used to obtain the casting deviations, and final finish requirement. It is very difficult to tell where the casting ends and the machining starts, and little (if any) hand blending is the ultimate goal.

We consider this to be on the cutting edge of the market with a large untapped growth potential in Trailing edge removal of Airfoil blades, and precision gate removal of complex castings in all material.

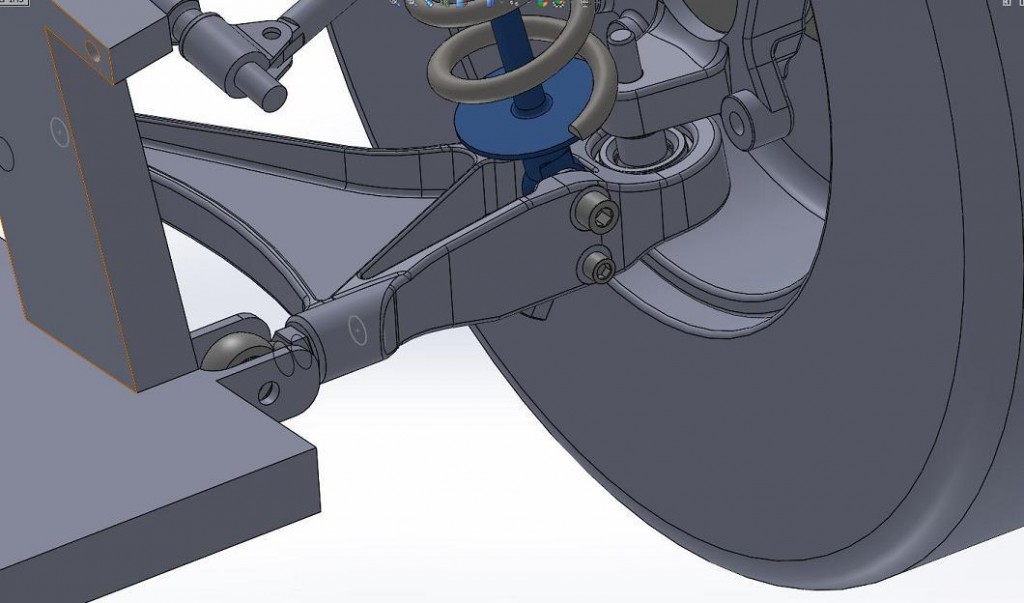

Billet Machining

Custom lower control arm for a race car as an example of our 5-axis CNC capabilities.