MetBase is our own proprietary database software, written in house for our use. It provides ISO 9001 & AS9100 compliancy for traceability and retrievability of inspection data and all robotic programming. Metbase has full forward and backward revision control on all CMM/CNC programs and everything is managed from within. It is the heart of our engineering capabilities with data mining being our primary tool. Whether we ran your part(s) one week ago, or 15 years ago, we have the ability to view/sort that historical data quickly. Custom reports, automatic exports from CMM runs, external line fitting , and statistical tools are just a few of the powerful tools available on all cataloged CMM runs. We are constantly improving and adding new tools and functionality.

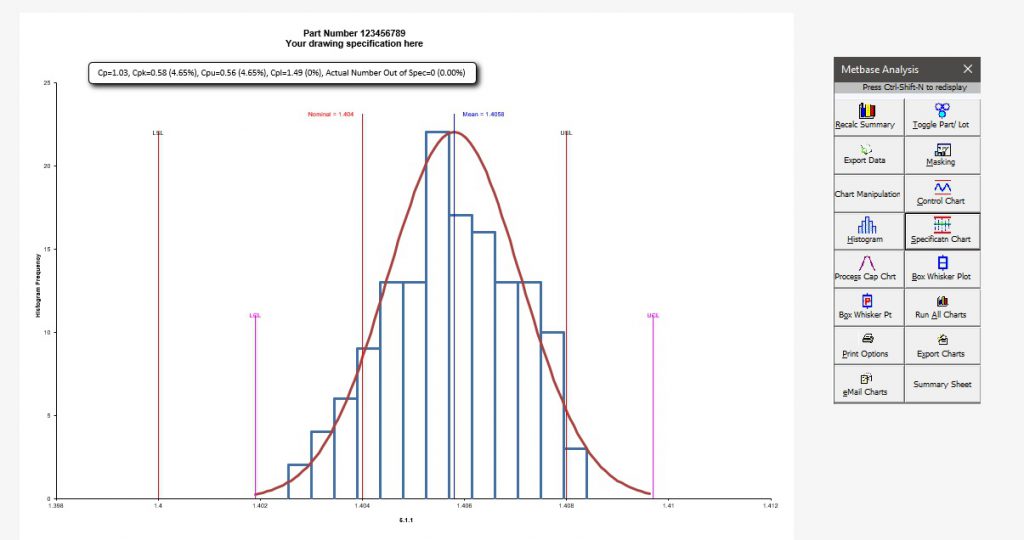

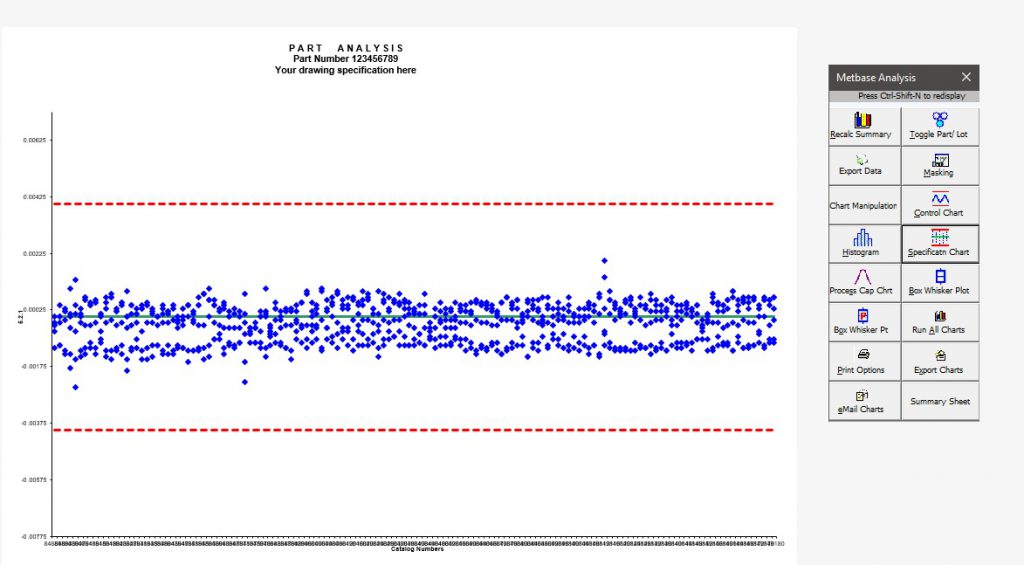

Metbase Analysis is one of our main analysis tools. Initially developed for customer capability studies, it is also at the heart of our machining process monitoring. Below are a few examples of on-the-fly charts that can be created from datasets.

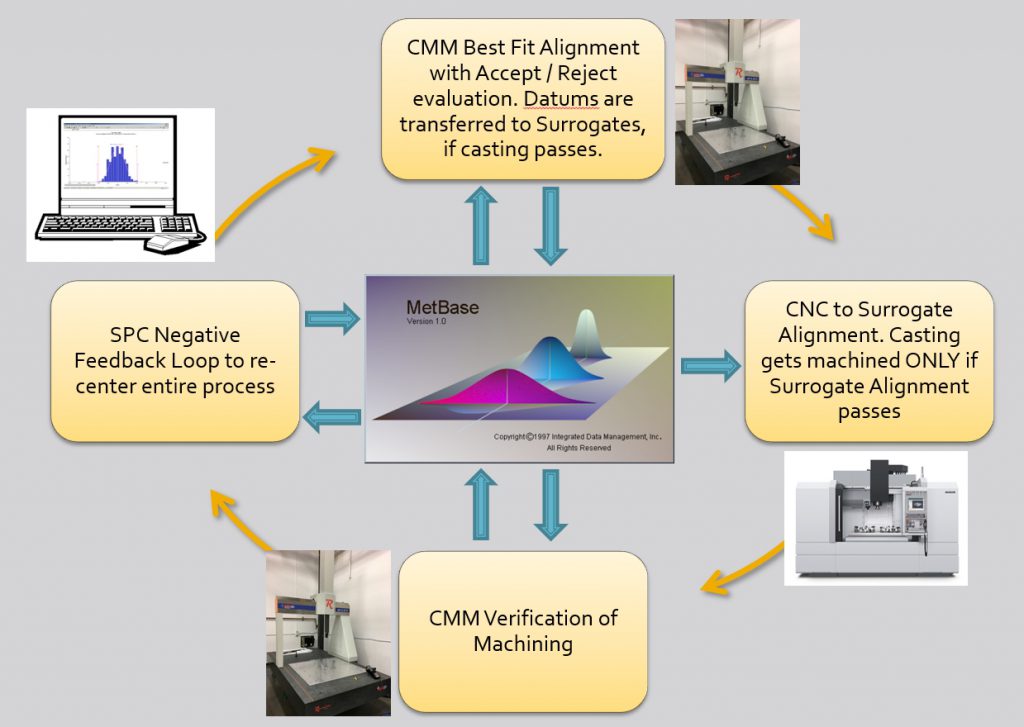

Metbase also allows us to link various pieces of equipment so that they may “talk” to one another. Obtaining a custom fit on a CMM run and being able to transfer that to a CNC that cannot, is our bread and butter. The software can not only transfer the alignment, but has traps in place to ensure there are no lot or serial mixups. Being able to link machines in a relational database and have all of our data in one place, allows us to have a closed loop system where we can constantly improve our process.